In 2012 the EPA adopted a new strategy for testing the range of battery electric vehicles known as the Multi-Cycle Test (MCT) procedure. This MCT method, from the SAE J1634 standard, uses a single full depletion test to determine range and AC energy consumption for multiple drive cycle types.

As the vehicle is driven over several iterations of the standardized drive cycles on a chassis dynamometer, the EPA measures the energy drawn from the battery pack over each cycle. The vehicle’s total usable battery energy (which is obtained by charging the fully depleted battery following the MCT test to its fully charged state, and is not the total energy content of the battery) is then used to determine the electric range for each drive cycle type.

Overall efficiency is calculated from the cycle data by accounting for the charging efficiency of converting AC electricity to DC electricity to be stored in the battery.

Why not all of the cycles are used to calculate EV range

The standard MCT test procedure consists of four UDDS cycles and two HWFET cycles in a specified sequence including mid-test and end-of-test constant speed “depletion phases” which vary in duration depending on the vehicle and the size of its battery pack.

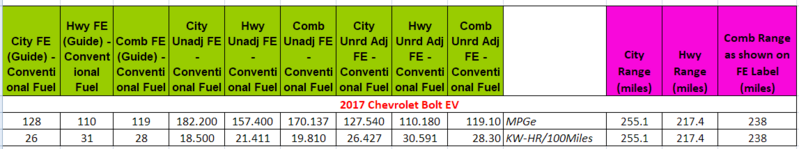

At present, only the UDDS and HWFET are required for EPA certification of a battery electric vehicle – if no other cycles are run, as is typically the case, the range and efficiency values are estimated by applying a correction factor of 0.7 to the UDDS and HWFET results to estimate the effect of the three supplementary cycles mentioned above.

Additional minor corrections are then applied to the test-obtained values before the final range and efficiency numbers go on the label.

But wait, electric vehicles are known to be significantly affected by both warm and cold temperatures - shouldn’t their impact be tested using the specially designed supplementary cycles rather than approximated with an equation? In theory, EPA official Rob French of the National Vehicle and Fuel Emissions Laboratory told Torque News. How to apply the supplementary cycles to directly evaluate these impacts, however, is not yet clearly defined.

As Mr. French pointed out, it would be difficult and time-consuming to accurately evaluate the effect of, for example, air conditioning use. In his words: “The AC [SC03 air conditioning] test is meant to capture the initial impact of AC as it works to bring the cabin temperature down after being soaked in the hot sun at 95 degrees,” he wrote in an email. “Once the cabin temperature is stabilized, the AC has to work a lot less hard, and the impact on fuel consumption diminishes. So simply running a [battery depletion] test with the AC on will dilute the impact that the 5-cycle value is intended to represent.”

The time-consuming issue comes into play because each proper AC and cold test requires that the vehicle “soak” in the prescribed temperature before the test for up to 12-36 hours in order to obtain consistently accurate results. And as French also mentioned, not much is known about the impacts of AC and cold temperatures at varying battery state-of-charge.

Finally, the 5-cycle test procedure was developed specifically for gasoline and diesel vehicles and its applicability to electric vehicles may be questionable. But at the moment it is the best we have, as we remain in the early days of electric vehicles.